We are distinguished manufacturers, traders, exporters and suppliers of extruder machines. Our comprehensive range is acclaimed for dimensional accuracy, hard wearing construction, seamless operation and versatile industrial applications.

About Us

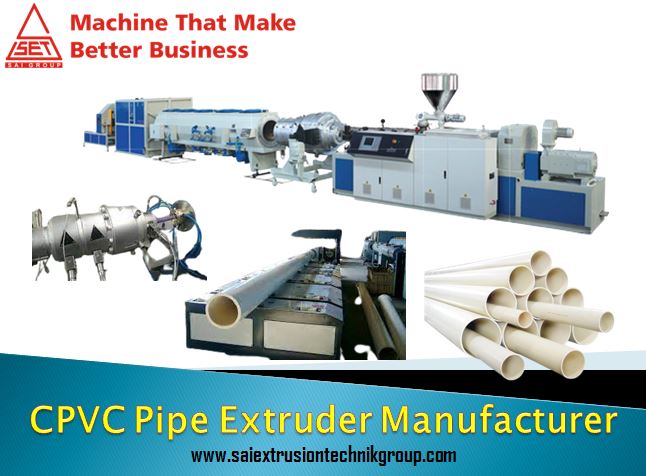

We Are a Leading Manufacturer, Exporter, Supplier & Trader of various Plastic Processing Machinery (Extruders) for the production of HDPE Pipe, PP-R 3 Layer Pipe, PLB Duct Pipe, Drip Irrigation Round & Flat Tube Extrusion, Twin / Single Screw RPVC Pipe, Casing Caping, Soft PVC Garden Pipe, Suction Pipe, Braided Pipe, LLDPE Pipe, Mulching Multilayer Film and Granule / Dana Making Plants etc. Since the year 2005.

We apply variety of combinations and versions to make our range highly applicable under thoughest of working conditions. The critical solutions our products offer to the to the requirements of industries such automobile,construction,electrical and eclectronic industries, medical and pharmaceutical industries makes us trusted business associates of clients spread across industry vertical.

Our products

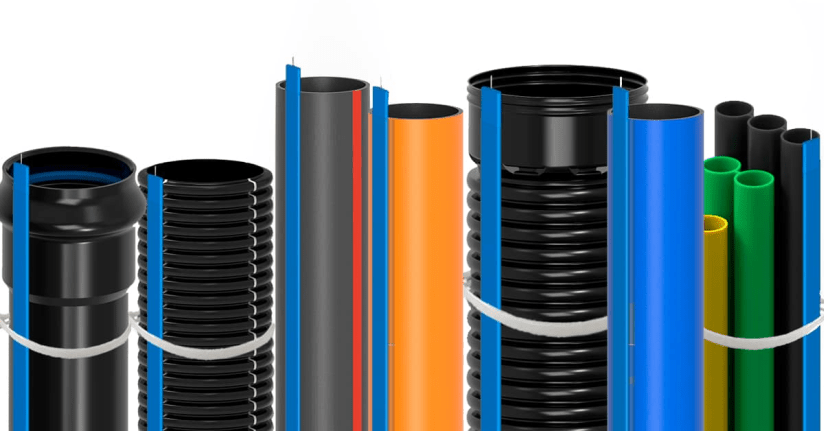

- HDPE Pipe Extrusion Line

- LLDPE Pipe Extrusion Lines

- Soft RPVC Garden Pipe Extrusion Lines

- Flat Drip Irrigation Pipe Extrusion Lines

- Suction Hose Pipe Extrusion Lines

- PP-R 3 HDPE Pipe Extrusion Lines

- PLB DUCT HDEP Pipe Extrusion Lines

- Round Drip Irrigation Tube Extrusion Line

- Single screw RPVC Pipe Extrusion Lines

- Plastic Reprocessing/ Granule Extrusion Line

- Octagonal Vacuum Tanks Line Equipments

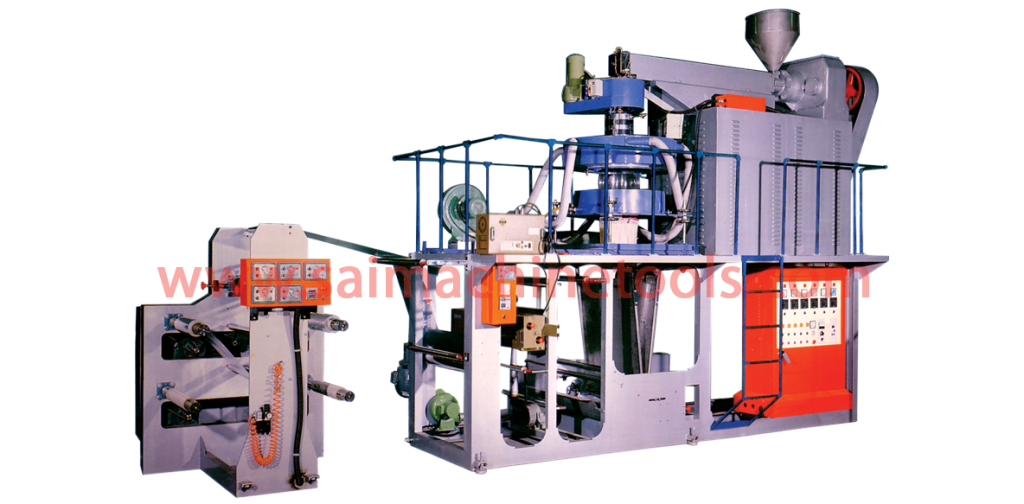

- Blown Film Extruder Extrusion Lines

- Haul Offline Equipments

- Spray Cooling Tanks Line Equipments

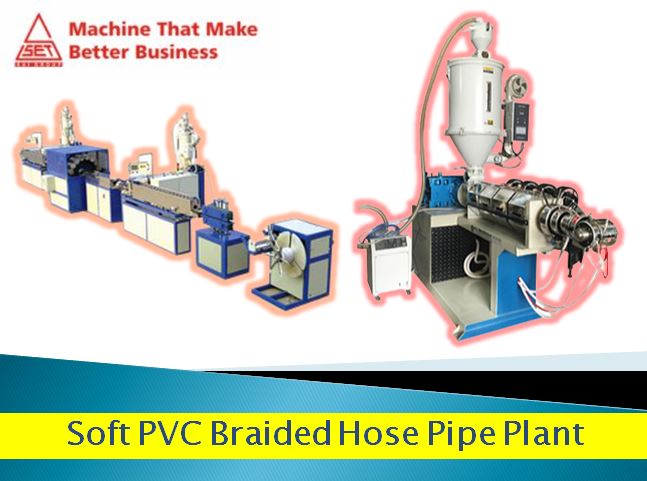

- Braided Hose Pipe Extrusion Lines

- Post Plastic Pipe Extrusion Lines equipment

Contact us

Office : Plot No. 75-77, Sector D-2, Industrial Area, Sanwer Road Indore- 452015,(M.P) India

Phone : +91 731-2971234 Fax : +91 731- 2971234

Mobile : +91 9827010234 , +91 8889588852

Email : shreesaiextrusiontechnik@gmail.com