Twin-screw extruder is that the classic machine used for the plastic extrusion process when two or more ingredients are mixed or Compounded. The method is best suited when extruding reactive polymeric materials.

Twin-screw extruder is especially useful within the production of rigid PVC and wood fiber blends. It offers higher process productivity as compared to one screw extruder. The worth of a twin-screw extruder is comparatively higher due to the complex nature of the machine while the only screw extruder structure is straightforward and low priced.

Advantages of dual screw extruder:-

High torque, high speed:-

The twin-screw extruder has developed new models with higher torque, higher speed, and lower consumption, and high-speed brings high productivity. Therefore, it’s special in processing materials of high viscosity and warmth sensitivity.

Increase labor efficiency:-

When repairing or within the maintenance of machines, just loosen some bolts on the split twin-screw extruder, activate worm gearbox handle and lift the upper half the barrel to open the entire barrel, compared to the standard twin-screw extruders, which are required to get rid of heating and cooling systems first, then pull out the entire screw, the split twin-screw extruder can shorten the repair time and lower the labor intensity.

Know the conditions of the wearing parts timely:-

It makes it easier to understand the wearing conditions of screw components and barrel inner liner, so on repair or remove the worn parts in time, rather than causing problems on the extruded products, and leading to unnecessary waste.

Reduce production cost:-

When within the manufacture of masterbatch, it often requires to vary colors or to vary products if necessary. For the overall twin-screw extruder, analyzing the blending process through opening the machining area during a jiffy , or by watching the melt profile across the screw. This will be simpler. Quickly opening the barrel of the split twin-screw extruder to possess manual cleaning rather than using detergent, so to save lots of the value .

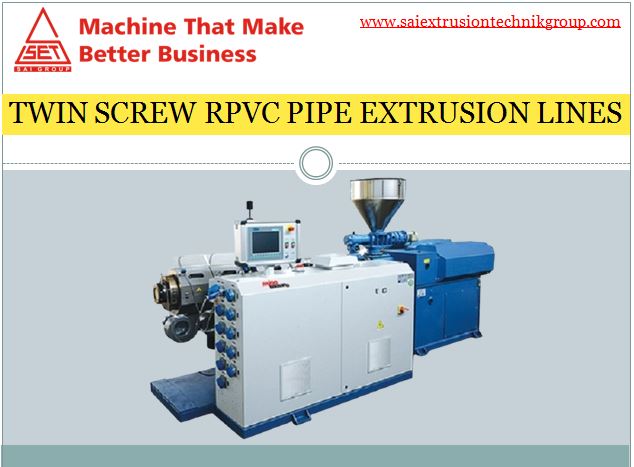

Shree Sai Extrusion Technik Pvt. Ltd is a leading Manufacturer, Exporter, Supplier & Trader of Twin-screw extruder and various Plastic Processing Machinery (Extruders).

Top-quality Twin-screw extruder is manufactured by Shree Sai Extrusion Technik Pvt. Ltd in Indore and supplied all over India.

Model of plants is available at Shree Sai Extrusion Technik Pvt. Ltd: SSET 52/18V to SSET 92/28V

If you want to buy any Plastic extruder machine then click on the below button

Our products

- HDPE Pipe Extrusion Line

- LLDPE Pipe Extrusion Lines

- Soft RPVC Garden Pipe Extrusion Lines

- Flat Drip Irrigation Pipe Extrusion Lines

- Suction Hose Pipe Extrusion Lines

- PP-R 3 HDPE Pipe Extrusion Lines

- PLB DUCT HDEP Pipe Extrusion Lines

- Round Drip Irrigation Tube Extrusion Line

- Single screw RPVC Pipe Extrusion Lines

- Plastic Reprocessing/ Granule Extrusion Line

- Octagonal Vacuum Tanks Line Equipment

- Blown Film Extruder Extrusion Lines

- Haul Offline Equipments

- Spray Cooling Tanks Line Equipments

- Braided Hose Pipe Extrusion Lines

- Post Plastic Pipe Extrusion Lines equipment

Contact us

Office: Plot No. 75-77, Sector D-2, Industrial Area, Sanwer Road Indore- 452015,(M.P) India

Phone : +91 731-2971234 Fax : +91 731- 2971234

Mobile : +91 9827010234 , +91 8889588852

Email : shreesaiextrusiontechnik@gmail.com