Plastic currently plays a huge role in our daily life. Plastics are used in almost all areas of manufacturing.

From bottles, credit cards to car dashboards, plastic are often a primary component. Due to the fact that most plastic is not biodegradable, a significant amount of plastic waste continues to build up around the world; with Industrialized countries contribute the largest amount of plastic waste.

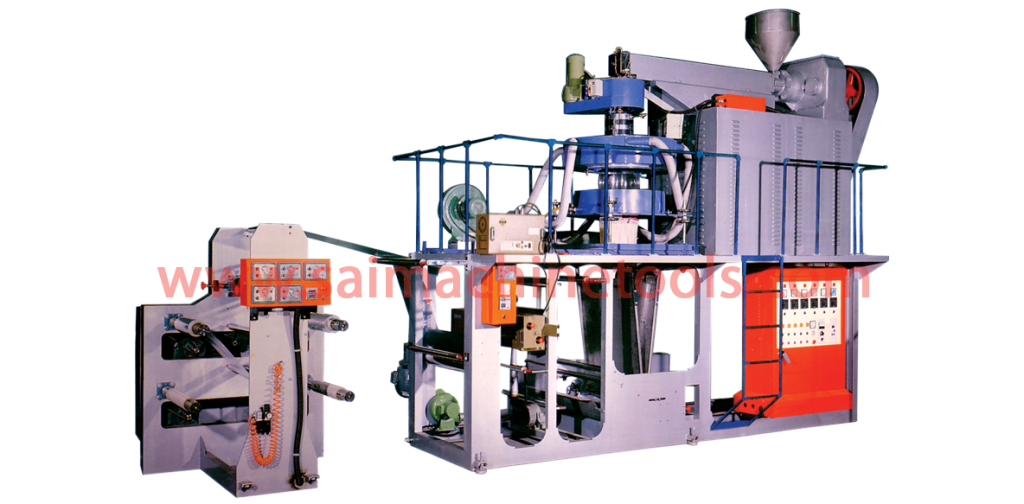

Plastic reprocessing extruder Machine

The waste polymers are efficiently processed in uniform manner and then further used for manufacturing products in various industries.The recycling plant is widely recommended across industries for its high output rate along with low power consumption. We use high quality components and materials in manufacturing the plant in strict tandem with industry standards.

How Plastic Reprocess Extruder Works?

Plastic extrusion is a process for converting plastic materials from solid to liquid states and reconstituting them as finished components. First, plastic pellets are gravity fed from a hopper into a jacketed screw.

As the screw turns about its axis, it transports, melts, and pressurizes the plastic. From there, the molten material is forced through a die that shapes it into a specified cross-section, producing parts with a potentially wide range of lengths. During extrusion, plastics transform from solid to liquid and back again without sacrificing their distinctive properties. As a result, scrap parts can be ground and re-extruded with minimal degradation, making extrusion a popular method for reducing or recycling plastic waste.

Advantages of Plastic Reprocess Extruder

Ø Plastic extrusions manufacture a spread of plastic products, starting from pipe and tube to plastic sheet and wire insulation.

Ø Plastic extrusion may be a manufacturing process that uses a high amount of plastic material to manufacture and produce endless profile.

Ø The process of extrusion is employed to manufacture fixed cross-sectional profiles. The plastic or thermoplastic material is pressed to make the specified shape and cross-section.

Shree Sai Extrusion Technik Group – Plastic Extruder manufacturer

If you are looking for excellent quality Pipe Extrusion Machines, Shree Sai Extrusion Pipeline Machines is the one that takes your business to the next level.

Manufacturing in bulk and that too with a highly Automatic pipe extrusion machine is the key to a successful production line.

Web Site: www.Shreesaiextrusiontechnikgroup.com