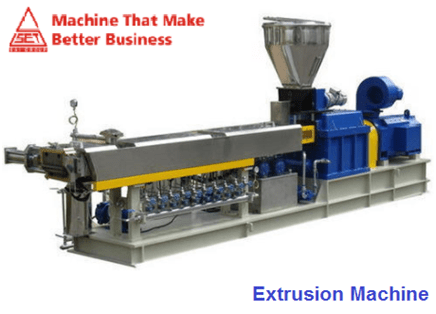

We design and manufacture The PPR Pipe Extruder Machine which is a very strong PPR Pipes. This Extruder machine or Plant is designed to manufacture quality water system pipes to be utilized in construction also as centralized heating systems. Designed for building applications including other hot/cold water-based.

PPR pipes have better resistance to heat and have a maximum temperature of 95°C. Moreover, these pipes are also highly preferred for water system and drainage-based applications and delivered in required construction specifications.

Ease of use & Integration

As a component of a PPR pipe assembly line, the mixing options offered by the extruder are critical to the operation of the extruder. To reinforce the straightforward connectivity and operation of the integrated extruder machine alongside other features like the assembly line from your extruder allowed regulating.

Quality Standards

Every single production process of our company pipe extruder machine performs quality checks at every step. And being an ISO-certified organization. We offer our range of Machinery as per the international quality standards. We procure high-grade steel and precision machines for manufacturing extrusion machines like Screws, Barrels, and Dies to form sure flawless products.

Shree Sai Extrusion Technik Group

Shree Sai Extrusion Technik Pvt. Ltd. Is a Leading PP-R Pipe extruder manufacturer in Indore (Madhya Pradesh) for the assembly of PPR pipe Extruder, PP pipe extruder, Irrigation Pipe Machine, LLDPE Extrusion Line, PVC compound Mixer, etc.

Our dealings remain sensitive to the precise needs of the customer. And our team continuously adheres to product innovation, development, and quality enhancement programs.

Web: www.saiextrusiontechnikgroup.com

Email: shreesaiextrusiontechnik@gmail.com

Phone: +91 9827010234, +91 8889588852