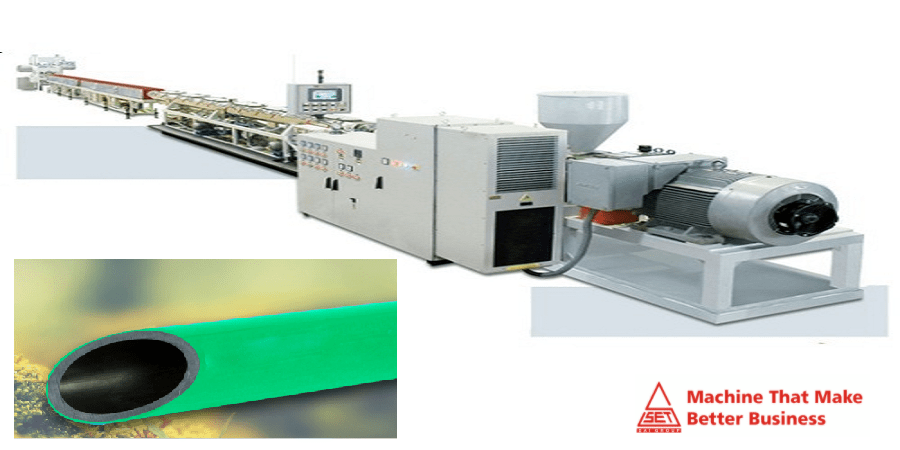

Twin screw extruder is the classic machine used for the plastic extrusion process when two or more ingredients are mixed or compounded. The process is best suited when extruding reactive polymeric materials. A twin-screw extruder is particularly useful in the production of rigid PVC and wood fiber blends. In this method, two screws rotate with or against each other and have special mixing features such as kneading block and forward and reverse capabilities, etc.

Advantage of this Machine:

In a twin-screw or multi screw extruder, there are two screws. Even if a modestly sized extruder, these screws are highly efficient devices capable of processing several tons of plastic per hour. The flexibility of twin-screw extrusion equipment allows this operation to be designed specifically for the formulation being processed.

Best Extruder Machine Manufacturer in India

Shree Sai Extrusion Technik Pvt. Ltd is a leading Manufacturer, Exporter, and Supplier & Trader of various Plastic Processing Machinery (Extruders) in India. Top-quality Twin Screw RPVC Pipe Extrusion Lines is manufactured by Shree Sai Extrusion Technik Pvt. Ltd in Indore and supplied all over India.

Machine Key Features –

- Easy to install

- Simple handling

- Higher efficiency with save electricity

- Tough body construction

- Reliable working

- Cost effective

Field of Application –

- Manufacturing RPVC pipes

- RPVC dual conduit pipe

- PVC profile and PVC compounding

Special Attraction of Our Machine –

- We are a leading manufacturer and exporter of Twin Screw RPVC PIPE Extrusion Plant. The high quality Twin Screw Extrusion Plant manufactured by Shree Sai Extrusion Technik Group Pvt. Ltd.

- Offered RPVC extrusion machines are manufactured using supreme quality materials and components sourced from trusted vendors of the industry.

- Our RPVC extrusion machines are acknowledged for their impeccable performance and user-friendly design.

- These Twin screw extrusion machines are hugely demanded by various industries due to their high operational fluency and less power consumption.

- Further, these Twin screw extrusion machines are available in various specifications, according to the clients’ requirements.

- Moreover, our Twin screw extrusion machines can be availed at rock bottom prices.

Our products

- HDPE Pipe Extrusion Line

- LLDPE Pipe Extrusion Lines

- Soft RPVC Garden Pipe Extrusion Lines

- Flat Drip Irrigation Pipe Extrusion Lines

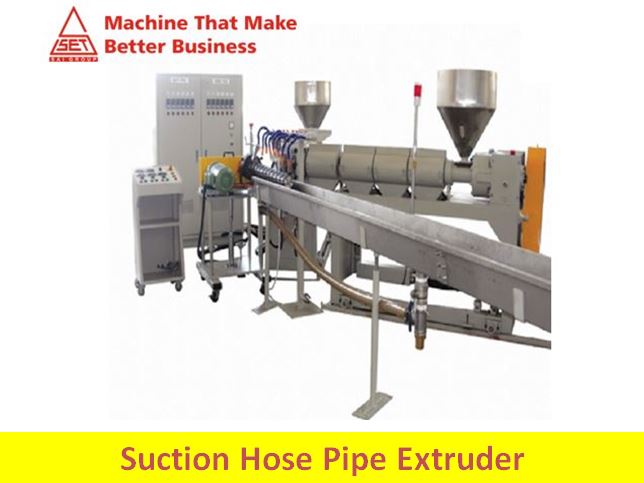

- Suction Hose Pipe Extrusion Lines

- PP-R 3 HDPE Pipe Extrusion Lines

- PLB DUCT HDEP Pipe Extrusion Lines

- Round Drip Irrigation Tube Extrusion Line

- Single screw RPVC Pipe Extrusion Lines

- Plastic Reprocessing/ Granule Extrusion Line

- Octagonal Vacuum Tanks Line Equipment

- Blown Film Extruder Extrusion Lines

- Haul Offline Equipments

- Spray Cooling Tanks Line Equipments

- Braided Hose Pipe Extrusion Lines

- Post Plastic Pipe Extrusion Lines equipment

For more information about Twin Screw RPVC Pipe Extrusion Lines and If want to buy these machines, you can visit the website or contact.

Web: www.saiextrusiontechnikgroup.com

Email: shreesaiextrusiontechnik@gmail.com

Call: +91 9827010234, +91 8889588852