Shree Sai Extrusion Technik Pvt. Ltd. is the company that has grown for becoming the largest manufacturer of plastic extrusion plants in India. The company started the business in the year 2005 at Sector D-2, Industrial Area, Sanwer Road Indore.

The company is working under Sudhir Jaiswal (Managing Director). The company has tried in even enter the international markets from the beginning. The major aim of the company is to make innovation in the Extruder Machine in India through Research and Development.

Difference Between A Single Screw And A Twin Screw Extruder

Single screw extruder

In the single screw extruder, the solid conveying section is frictional drag and drag, and the melt conveyer section is sticky and drags. The friction properties of solid materials and the viscosity of the molten materials determine the transport behavior. If some materials have bad friction performance, if the feeding problem is not solved, it is difficult to feed the material to a single screw extruder. It is also known as plastics granulator machinery or molding processing machinery.

Twin screw extruder

A twin-screw extruder is the classic machine used for the plastic extrusion process when two or more ingredients are mixed or Compounded. The process is best suited when extruding reactive polymeric materials. A twin-screw extruder is particularly useful in the production of rigid PVC and wood fiber blends. It offers higher process productivity as compared to a single screw extruder. The price of a twin-screw extruder is relatively higher because of the complex nature of the machine while a single screw extruder structure is simple and low priced.

Shree Sai Extrusion Technik Pvt. Ltd. is one of the best industries engaged in offering various Plastic processing machines in the market. To manufacture these products, experienced professionals make sure to follow the quality assured standards of the industry. Also, these products are rigorously checked on different norms of quality, and technology before the final delivery to the clients.

Our products

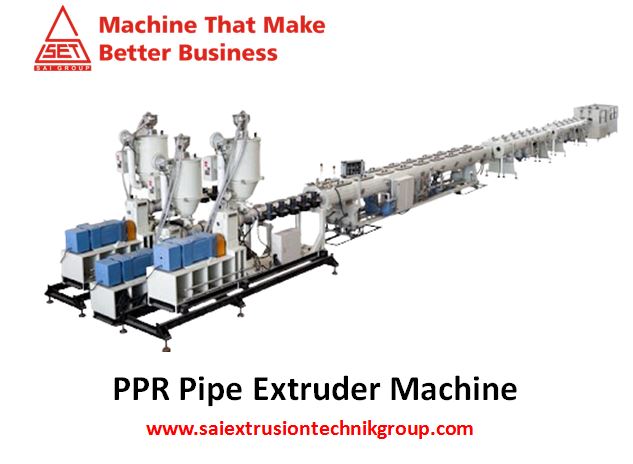

- HDPE Pipe Extrusion Line

- LLDPE Pipe Extrusion Lines

- Soft RPVC Garden Pipe Extrusion Lines

- Flat Drip Irrigation Pipe Extrusion Lines

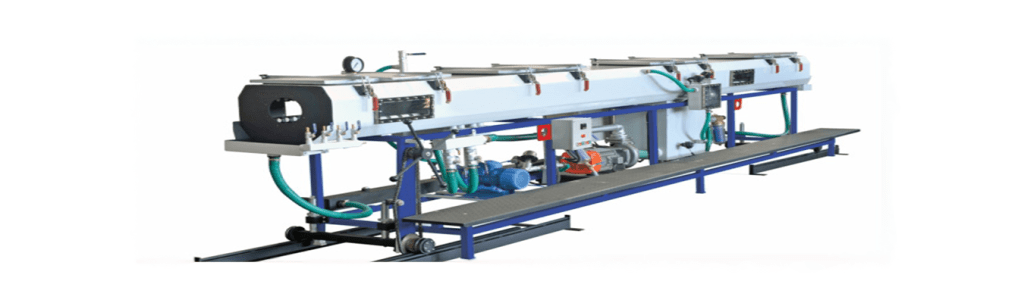

- Suction Hose Pipe Extrusion Lines

- PP-R 3 HDPE Pipe Extrusion Lines

- PLB DUCT HDEP Pipe Extrusion Lines

- Round Drip Irrigation Tube Extrusion Line

- Single screw RPVC Pipe Extrusion Lines

- Plastic Reprocessing/ Granule Extrusion Line

- Octagonal Vacuum Tanks Line Equipment

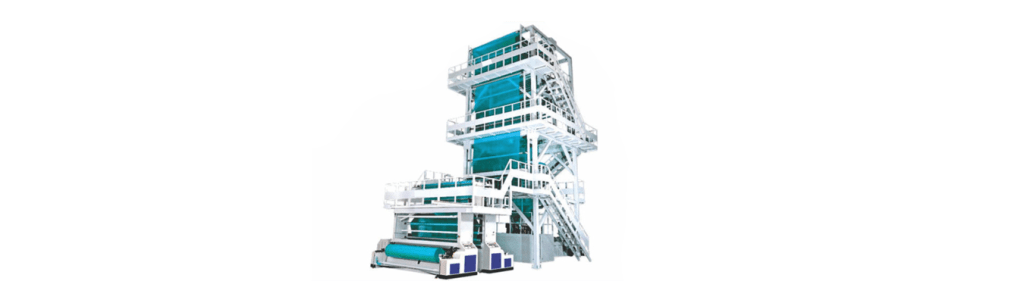

- Blown Film Extruder Extrusion Lines

- Haul Offline Equipments

- Spray Cooling Tanks Line Equipments

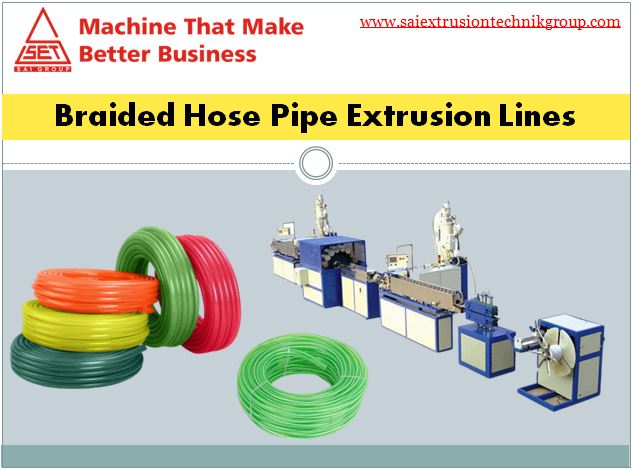

- Braided Hose Pipe Extrusion Lines

- Post Plastic Pipe Extrusion Lines equipment

For more information, you may visit our website here

Contact Us

Web: – www.saiextrusiontechnikgroup.com

Email: – shreesaiextrusiontechnik@gmail.com

Phone: – +91 9827010234, +91 8889588852