What is Extrusion?

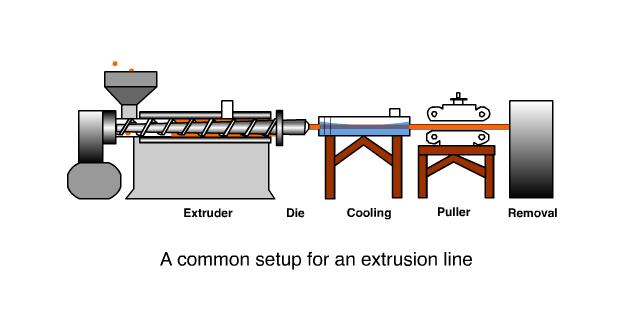

Extrusion is a type of forming process (which is a type of manufacturing process) in which a metal is confined in a closed cavity and then allowed to flow through only one opening so that the metal takes the shape of an opening.

In other words, it is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The extrusion process can be done with the material hot or cold.

Types of extrusion processes:

1. Direct (or forward) extrusion:

This method employs a power-operated ram and a container into which the metal is kept for confinement. A dummy block is used between ram and hot metal. Because of ram pressure, metal first fills the cylindrical shape and then is forced out through the die opening until a small amount is left in the container. Finally, it is sawed off next to the die and the butt end is removed.

2. Indirect (or backward) extrusion:

This process is similar to direct extrusion except that the extended metal is forced out through a hollow ram. No friction works between the metal billet and the container walls since the billet does not move the container. In comparison to direct extrusion, less force is required in indirect extrusion.

Advantages of extrusion:

- Low cost per part

- In hot extrusion, post execution alterations are easy because product is still in heated condition.

- Continuous operation

- High production volumes

- Many types of raw materials can be used

- Good mixing (Compounding)

- Surface finish obtained is good

- Good mechanical properties obtained in cold extrusion

Applications of extrusion process:

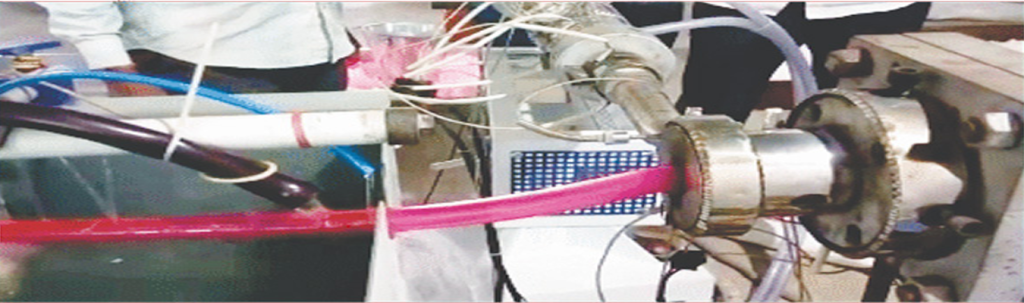

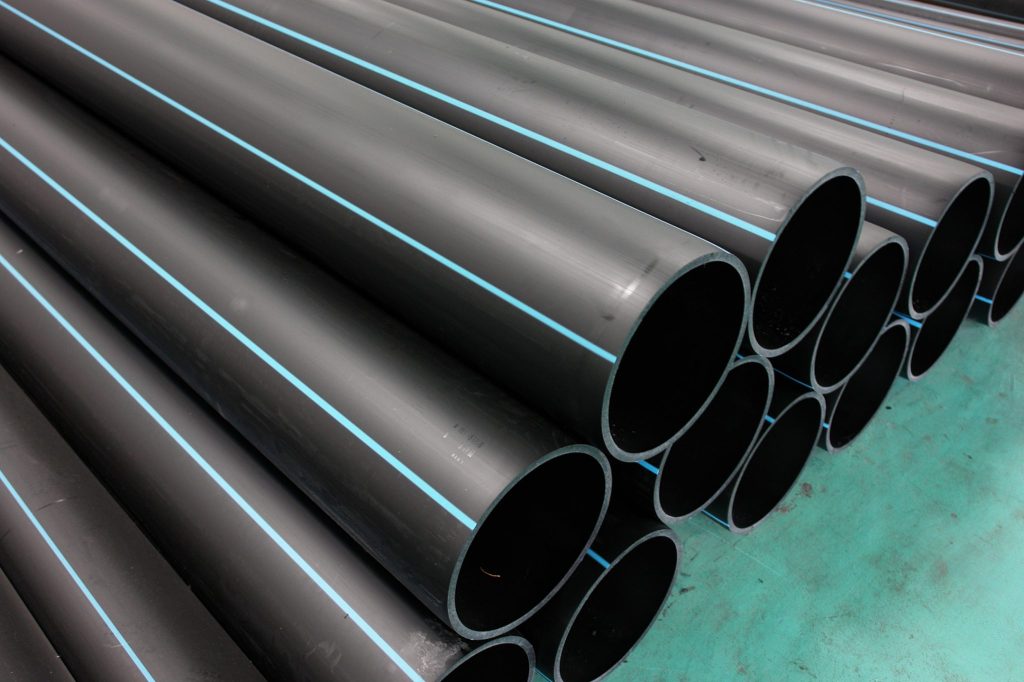

- Extrusion is widely used in production of tubes and hollow pipes.

- Aluminum extrusion is used in structure work in many industries.

- This process is used to produce frames, doors, window etc. in automotive industries.

- Extrusion is widely used to produce plastic objects.

- Electrical wires, bars and tubes are some of the items produced by hot extrusion.

- Collapsible tubes, gear blanks, aluminum cans, cylinders are some of the items produced by cold extrusion.

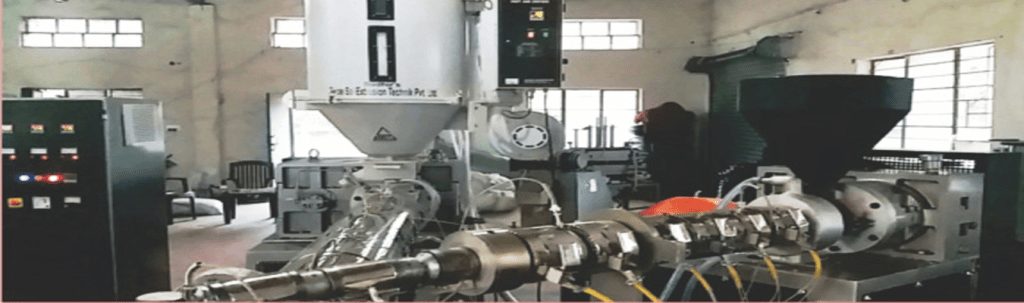

Shree Sai Extrusion Technik Pvt. Ltd. is leading manufacturer, exporter, supplier & trader of various plastic processing machinery (extruders) for the production of HDPE Pipe, PP-R 3 Layer Pipe, PLB Duct Pipe, Drip Irrigation Round & Flat Tube Extrusion, Twin / Single Screw RPVC Pipe, Casing Caping, Soft Pvc Garden Pipe, Suction Pipe, Braided Pipe, LLDPE Pipe, Mulching Multilayer Film And Granule / Dana Making Plants Etc. Since The Year 2005.

They apply a variety of combinations and versions to make them highly applicable under the toughest of working conditions. The critical solutions our products offer to the requirements of industries such as in an automobile, construction, electrical and electronic industries, medical and pharmaceutical industries makes us trusted business associates of clients spread across industry vertical.

For more information you may visit our website here –

Contact Us

Web: – www.saiextrusiontechnikgroup.com

Email: – shreesaiextrusiontechnik@gmail.com

Phone: – +91 9827010234, +91 8889588852